Table of Contents

Chapter I: Evolution Toward JUPITER Development

Chapter II: Buildup for JUPITER Development

Chapter III: Army-Navy Cooperative Program

Chapter IV: Operational Control to the Air Force

Chapter V: The System

Chapter VI: Training

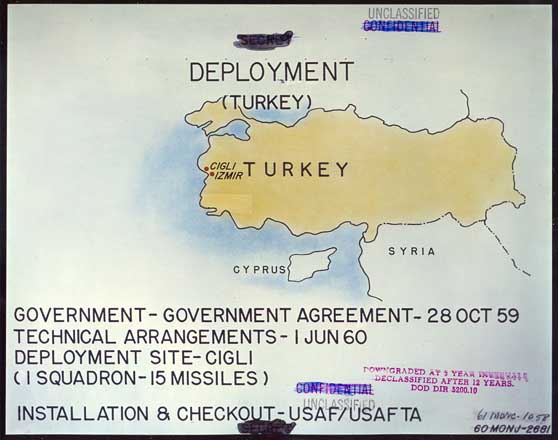

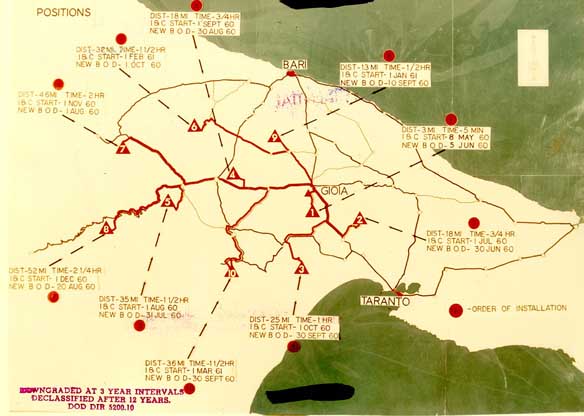

Chapter VII: Deployment

Chapter VIII: Program Dividends - Satellites

See the JUPITER photo collection

|

Chapter I: Evolution Toward |

|

The 1,000-Mile Missile DA did not concur with AFF’s 150- and 500-mile range proposals. Instead, they felt that efforts should be concentrated on developing one missile capable of a 1,000-mile powered flight and of being accurately guided the last 200 miles at a speed of Mach 3. Indications were that development of the 1,000-mile missile would start immediately, but on 2 August 1954 the Army Chief of Staff directed further study covering surface-to-surface missile requirements. During the course of these events, and even prior to the dates indicated above, personnel at Redstone Arsenal, where most of the existing Army know-how for missile development was concentrated, advised OCO that a 15-month study on a long-range missile had been prepared and was being submitted for review. Also, germane to the proposed development plan was the fact that the personnel corps at Redstone had reached a scientific point of achievement where assignment of a challenging new project would be quite welcome. In brief, Redstone suggested that it be directed to initiate the 1,000-mile missile development program. The Redstone study concluded that the best approach would be the development of a ballistic, two-stage rocket-propelled missile, with the warhead separating from the second stage after burnout. This proposal was based on a probable need for a controllable warhead; but, if this device were unnecessary, feasibility studies should consider the development of a single-stage, rocket-propelled ballistic missile. Propulsive agent proposals involved gasoline and liquid oxygen (LOX), which was consistent with the then state-of-the-art and availability. While these recommendations were being made, Redstone Arsenal was becoming more and more capable of initiating the long-range missile program, for the REDSTONE missile had, by that time, traversed a number of successful flights and could be used as a carrier in a component development program. A suggestion to this effect was made, especially with regard to experimental nose sections, as it was known that the re-entry problem for long-range missiles would be difficult to solve. The initiation seemed logical, too, from another standpoint, for North American Aviation (NAA) was on the verge of developing a power unit capable of 135,000 pounds of thrust, which could be either adapted to the REDSTONE or used in new missile development. Eventually, many of the recommendations of the Redstone group were adopted, that is, with reference to the technical pursuit, but not in 1954, for DA and DOD felt that further study was necessary. Redstone was persistent, however, for as late as December, proposals for long-range missile development were forwarded to OCO. Reactions were mild. At the outset of 1955, it appeared that the cycle of study and propose was to continue, when OCO directed Redstone to make a study of a family of missiles for Army use. To some extent, this did remain the pattern, but informal information gleaned by OCO in February eventually brought changes. With regard to the continuing studies, a July proposal for a 1,500-mile missile led to a specific development program. As for the February item, OCO learned that the Air Force intended to invite proposals for the development of a 1,000-mile missile using existing hardware. An announcement had also been made in January by the Air Force confirming the fact that Convair was working on the ATLAS 5,000-mile ICBM. These Air Force announcements fostered a wave of activity on the part of the Army, especially with regard to the 1,000-mile missile. To Army, depending on the use of the 120,000-pound thrust NAA engine its facilities appeared to be the logical site for development. It was felt that the REDSTONE could be upgraded to a two-stage missile having a range of 1,000 miles or better. Besides, the guidance system was being developed, and which of the hardware required for such a weapon had already been proven. Personnel and facilities at Redstone Arsenal could admirably satisfy the requirement, and OCO proposed that these be offered. The 1,500-Mile Missile The thinking in terms of range did not stop with the idea of the 1,000-mile missile, for on 14 February 1955 the Technological Capabilities Panel, commonly known as the Killian Committee, recommended an immediate program leading to the development of small artificial satellites and an IRBM of the 1,500-mile range class to parallel ICBM development. Missiles of such range actively affected the concept of waging warfare and, in this respect, the Army Deputy Chief, Research and Development (R&D), queried OCO as to the possibility of a 1,000- to 1,500-mile missile. There were a number of matters to be considered. For example, according to the R&D chief, airlifted assaults over great distances might characterize Army operations, and the transport of such weapons as the REDSTONE and SERGEANT to airheads might pose a serious logistic problem. Therefore, the launching of a long-range ballistic missile from a relatively rear area might prove quite effective as well as economical. Before such a concept was adopted, however, there were salient questions to be answered. These involved the degree of accuracy that could be achieved, reliability of guidance systems that might be employed, and whether or not problems in either case could be speedily resolved. This was but one move in the slightly quickened pace leading toward action, for, on 25 March, the Assistant Chief of Staff, G-3 (Training), recommended the initiation of the 1,000- to 1,500-mile missile development program. Additionally, CONARC began reviewing and updating its 1954 conceptions. Proposals for short range remained the same, with the 75-mile SERGEANT being considered as the best solution to meet this requirement. In the medium-range field, development of a 250-mile missile was proposed to replace the suggested 150-mile weapon. As for long-range missiles, CONARC did not make a specific suggestion. The 250-mile missile, to their thinking, deleted the 500-mile requirement; however, they believed that the Army did require the ability to attack targets with nuclear warheads at extremely long range. By May 1955, Redstone Arsenal completed the study that had been directed by OCO in January. Basically, this involved three missiles, the larger of which was an IRBM. No commitments were immediately forthcoming from this or any of the other preceding proposals, but at this point recommendations from widespread sources were centering on the requirement for a long-range missile of the IRBM class. Redstone Arsenal quite firmly believed that it had the capability to accomplish such development, so, in June, another presentation was made to Washington officials proposing development for a ballistic missile system of 1,000 or more nautical miles range. Throughout this study, it was repeatedly stressed that this development could be effected by redesign of existing components. The REDSTONE had served as an excellent laboratory and could still be used in such a way to test and prove long-range missile components. In fact, 19 REDSTONES had been earmarked for these purposes, especially with regard to resolving the nose cone re-entry problem. A number of alternative methods were included as to the way in which the missile could be employed, which involved ranges above and below the 1,000-mile mark. All of these proposals hinged on the use of NAA’s engine, which was now rated at 135,000 pounds of thrust and had undergone some 334 static tests. No active results came from this proposal. Continuing with the successive monthly proposals, Redstone Arsenal, in July, dropped all recommendations for shorter range and concentrated on the 1,500-mile version. As to characteristics of the weapon being considered, it was to be a single-stage, liquid-fuel ballistic rocket designed to carry a 2,000-pound payload to the specified range. A swivel-mounted 150,000-pound thrust NAA engine would be used as the power unit (static tests of engines of this capability had already been conducted). The missile would have a diameter of 95 inches and a length of 1,114 inches. Propulsion would be provided by using 45,860 pounds of JP4 as fuel and 103,120 pounds of LOX as the oxidizer to acquire a maximum burning time of 119.3 seconds. Launching weight would be 167,000 pounds. The missile was not fin controlled but, instead, would have attached two hydrogen peroxide vernier thrust nozzles of 1,000 pounds of thrust each. Additionally, six small nozzles would be installed to provide spatial attitude control in pitch, yaw, and roll. The gimbaled engines also served to assist in correcting the same problems, and the swivel would be hydraulically activated. The June and July proposals orally presented by Dr. Wernher von Braun, chief of the Redstone development team, before the Armed Services Policy Council began to interest officials at the high Washington level. Secretary of Defense Charles E. Wilson designated Reuben B. Robertson of DOD to investigate the IRBM field. Then, OCRD requested OCO to compile a list of facts favoring development of the 1,500-mile missile at Redstone. OCO quickly complied, listing many of the reasons that had been included in past studies, that is, facilities, competent personnel, and proven components that could be redesigned. One new feature was added: that the REDSTONE missile had been transferred to a production contractor. This meant that an industrial capability would be available when the 1,500-missile reached that stage, an important point to be considered. By August 1955, the matter had reached a cost study stage. In this respect, the Army Chief of Staff requested an estimate for developing a 1,500-mile missile at Redstone. OCO placed the cost of a six-year development program at $240 million, but OCRD believed this to be too conservative and estimated that the costs would run between $400 and $500 million. Redstone’s plans as of September indicated that the time frame of the development would be somewhat telescoped, giving an Ordnance Readiness Date of 1 November 1960. This plan was based on an assumption that the starting date of the program would be 1 October 1955 with the first flight test of a REDSTONE to support research mission assignments for development of the 1,500-mile missile. Fifteen such vehicles would be used in the first stage of the program. Thereafter, a 50-missile prototype test program was contemplated. For strictly R&D purposes, there would be 40 missiles. The other 10 missiles would serve the dual purpose of R&D and engineer-user testing and would be instrumented to satisfy both requirements. This planning was based on experience in the REDSTONE development program, and was the basis for OCO’s $240 million estimate. Department of Defense Decision Now that it was generally conceded that a requirement existed for a 1,500-mile range ballistic missile, the matter at hand was the adoption of the specific technical development pursuit from the several existing plans. For example, the development plan proposed by the Air Force in January 1955 was still active, and OCO as late as September was suggesting that the team at Redstone be used to accomplish the work. Air Force officials indicated that they would like to see the team broken up and assigned to its various activities to effect development, but Secretary of the Army Wilbur M. Brucker objected to such fragmentation. At this point, the Secretary of Defense, Charles E. Wilson, decided there would be two IRBM’s developed, one of which would cover land- and sea-based requirements. When this decision was made, DOD, in reality, had five possible systems under consideration for the IRBM role. One was simply to use a by-product of the ATLAS ICBM program and the others included a separate Air Force project, a United States (US)-United Kingdom (UK) cooperative development program, a Navy ship-based ballistic missile, and the Navy TRITON missile. Most of these courses appeared illogical to Army technical experts. With regard to the ATLAS by-product, the high ICBM development priority and the anticipated operational date of the ATLAS—1965—made this possibility seem a poor choice. The UK had little experience and it would be 1965 before a product would result from a cooperative venture. TRITON was nonballistic, so it was completely ignored. With regard to Air Force and Navy projects, Army believed that these could be combined and the group at Redstone Arsenal could develop and have the system available by 1960. Also—in September— Dr. von Braun gained an audience with Mr. Wilson and pointed out that the development of the 1,500-nautical mile missile was a logical extension of the REDSTONE program. Some effect on the development course must have resulted from this particular presentation. The pace accelerated in September and October 1955. An Army staff proposal presented to DOD on 22 September called for a program embracing the recommendations of the Redstone Group, that is, use of facilities and personnel, design assumptions, and cost estimates. On 13 October, the same presentation was made to the Chairman of the Joint Chiefs of Staff (JCS). Then, on the 26th, the Army Chief of Staff announced to his key subordinates a plan to execute the 1,500-mile missile development program, if the Army were assigned program responsibility. This plan outlined the role that the later-to-be-activated Army Ballistic Missile Agency would play. It also gave indications that the commanding general of this organization would be delegated special authority, covering funding, development, and procurement actions, to execute the program under a compressed time frame, even to requiring assistance from Army organizations outside his immediate command. Ways and means for conducting an IRBM development program were available, but one major question remained to be answered. This pertained to the employment of the missile when it had attained an operational capability. Simply stated, who was going to fire the missile—Army or Air Force? For years now the Army commanders had been envisioning a battlefield of considerable depth, which manifested the necessity for a long-range missile. Secretary Brucker defended this need before the National Security Council on 1 November, and pressed for a decision favorable to Army. The next day, the JCS indicated to Secretary Wilson there was an urgent requirement for IRBM development, but they could not agree as to the service to which it should be assigned. On the 8th the DOD decision was rendered, and an Army development program was given the "green light." Secretary Wilson’s decision covered the long-range ballistic missile program, which included two ICBM’s and two IRBM’s. All were to be afforded the highest national priority, with a qualifying stipulation that the IRBM’s were not to interfere with ICBM development. The Army, in cooperation with the Navy, was to develop IRBM Nr 2 to achieve an early land- and sea-based capability. To direct the program from the top level, a Joint Army-Navy Ballistic Missile Committee (JANBMC) was established, with the Secretary of Navy serving as Chairman and the Secretary of Army as vice chairman. They, in turn, reported to the Ballistic Missiles Committee, which the Secretary of Defense established in his own office (OSD/BMC). Secretary Brucker and General Maxwell D. Taylor, Army Chief of Staff, relayed the word to all Army elements that the IRBM Nr 2 program with to carry top priority in the Army. |

|

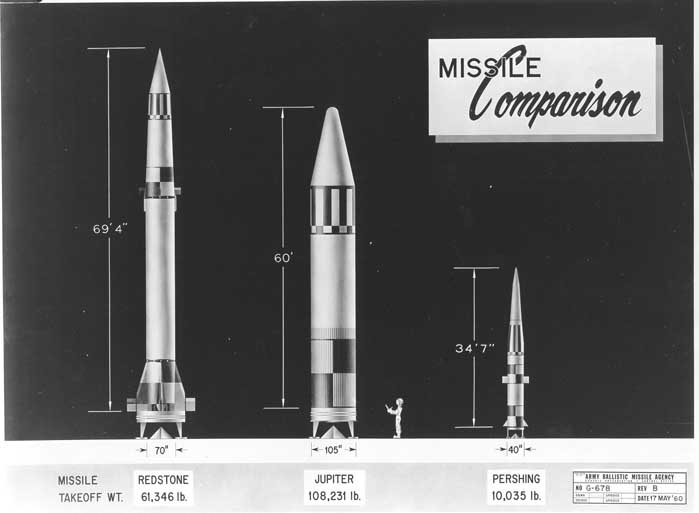

The next increment in the construction program came about in 1954, as a result of a growing national interest in missile research and development. This building effort included a test stand with ancillary buildings to permit testing of a complete missile under full thrust, a guidance and control (G&C) laboratory, and an engineering building (488, which was later renumbered 4488 and became the headquarters building of ABMA). When ABMA was activated, it inherited the new construction plus the old chemical warehouses. The crash nature of the JUPITER program (so named in April 1956) demanded additional structures, and 11 construction projects were considered absolutely necessary by ABMA. These, in part, included an addition to the structural fabrication building, a structures and mechanics laboratory, aft extension to the G&C lab, a guided missile test shop, a missile assembly-inspection hangar, and modifications to some of the 1954 construction. A total of $25 million was requested to satisfy these purposes. As it turned out, authority for $23,968,379 was received; and, on a balance sheet of 5 January 1962, the Mobile District of the Corps of Engineers (COE) reported expenditures of $22,087,451.21 against obligations of $22,087,459. Added to this, approximately $1.5 million had been spent on an engineering building at the Jet Propulsion Laboratory (JPL) in support of the JUPITER program. Thus, the construction program stayed well within its authority. Despite the crash connotation placed on the weapon’s development, the construction program did not move with the speed this implied. During December 1956, ABMA sent a message to OCO, the gist of which was largely justification for the facilities to be constructed, modified, or expanded. Moreover, ABMA pointed out that these facilities could be used at a later date, with little, if any, change for other guided and ballistic missile development programs. Only five projects had made any significant progress by 30 November 1956—10 to 30 per cent—and these were still a considerable time away from effective use. On the others, there was no progress or a mere one per cent. The situation of "make do" with what they had in 1956 was far from satisfactory. A good example, in this respect, although reported much earlier in the year than the December message, was the missile assembly and inspection hangar. As already stated, the original facility was constructed in 1953 to provide for the production of one REDSTONE missile per month. This facility was totally inadequate for the 1956 production work, and an expansion request was placed in the amount of $2.401 million. At that time, the production goal was two missiles per month, but there were other factors involved besides this. For one thing, the diameter of the JUPITER was 105 inches as compared with 70 inches for the REDSTONE, and special rigging was required. Moreover, fabrication was not limited to the JUPITER per se, for that missile was still a considerable time away from a frozen configuration. There were other test vehicles such as JUPITER A’s and C’s. This meant the likelihood of almost simultaneous work on several missiles that were of varying configurations, or even work stopped on one particular missile until component redesign could be effected on deficient parts discovered by the labs. Working space was a vital necessity. It is relatively simple to identify the source of the facility construction difficulty, as the slow pace was caused by the DOD roles and missions decision of November 1956, which, in part, stated that construction projects in support of anti-aircraft and ballistic missiles within the Army were being deferred without prejudice and returned for rejustification under the new ground rules (limitation of Army employment of missiles of 200-mile range and under). In reality, the FY 1957 MCA program did not feel the complete impact of this decision, for $15 million was already under contract, but the proposed FY 1958 MCA program was dealt a "body blow" with little time for reclama by Ordnance. Eventually, the late 1957 DOD decision to develop both IRBM’s brought construction more in line with requirements. Management Because of the scope of the development program and the charge to accomplish the task with speed, effective program management was a must. The Agency Commanding General was armed with unusual authority, that is, for a field commander, to carry out the order, but a chain of command still existed to assure that decisions were carried out in the best interest of the program. At the top of program control was DOD’s Ballistic Missile Committee (BMC) and, thence, downward to JANBMC. Subsequently, after the pull out by the Navy, the joint group was redesignated the Army Ballistic Missile Committee (ABMC). This management tier provided higher review authority and program control. Management at the working level was also an important factor. It was imperative that the organization have "on-the-spot" technical competence for every facet of the development program, and thus the headquarters staff was organized somewhat differently than normal. Extensive coordination usually breeds delay, so the move was made to bring the experts of the various technical services and other organizations to the development installation. In this respect, COE, Transportation Corps, and Signal Corps were represented. Besides this, representatives of the combat arms and pertinent Department of Army staff offices were domiciled at ABMA. These individuals served in dual roles—staff members of ABMA and representatives in the interests of their parent organizations. Direct communications were made possible with all necessary sources, which reduced the reaction time in settling specific technical problems. This cooperation promoted early and valid decisions with regard to program direction. |

|

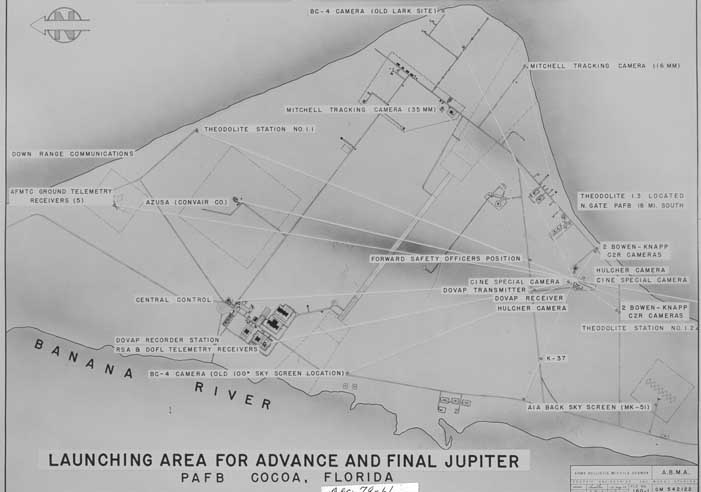

Chapter III: Army-Navy Cooperative Program DOD’s decision relative to the joint cooperative effort between Army and Navy to develop IRBM Nr 2 did little to deter the Redstone group’s development plans, although in the very recent past they had been studying to satisfy either Amy or Air Force requirements. Since the Navy was now in the program, the configuration of the proposed missile would have to change drastically to suit shipboard or possibly submarine operations. Development Plans As may be recalled, the Secretary’s decision was made on 8 November 1955, and by the 28th of the month General Medaris presented a tentative development plan to OSD-BMD that had been previously approved by JANBMO. The Navy, too, had reacted quickly, for on 17 November a Special Project Office (SP0) was created with Rear Admiral W.F. Raborn appointed director. SP0 was established to handle problems associated with the ship-launched version of the JUPITER weapon system. Prior to the start of actual development operations, the Army and Navy worked out ground rules as to which service would accomplish a specific function or task. According to DOD, both services were to agree upon military characteristics (MCs) and performance for a single land- and sea-based missile. ABMA was responsible for developing the basic missile, and operational objectives for both employment concepts were to be accomplished simultaneously rather than compromise Navy work to gain an early land capability. The Navy was charged with the responsibility of selecting a contractor for developing a system that was capable of accepting and launching the Army missile. This was later designated the ship inertial navigation system (SINS). To promote a cooperative atmosphere at the working level, Navy and Army liaison offices were established and manned with technical personnel at ABMA and the Navy development site, respectively. Returning to the tentative development plan, the brevity between decision and submission prevented any detailed presentation on MCs or specifications, for they were not then available. Despite the preliminary nature, there were some directed requirements and some known design characteristics to fulfill the goals. In this respect, a maximum range of 1,500 miles was to be attained, and calculations had been made on several versions that could reach this distance. The proposed types were from 50 to 65 feet long, and weighed between 85,000 and 115,000 pounds. Both figures were considerably shorter and lighter than the 1955 proposal for an Army land-based IRBM. ABMA intended to start development on a vehicle involving the greater weight and length cod, as engineering and flight experience permitted, move toward the smaller version. The plan went on to discuss the environment the missile would experience from lift-off to impact, and the reactions on the part of the missile to meet the demands of this situation. Over all, the 1,500-mile missile development program would be dependent on work that had been accomplished in behalf of the REDSTONE, and mention was made of the continued importance of funding this program. This remark was prompted by the fact that JUPITER component development activities would begin with the firing of a REDSTONE in April 1956, and after that 35 more of these missiles would be used in support of JUPITER development. According to ABMA plans, major assemblies and components or subcomponents would be procured from prime contractor production, and would be modified at the arsenal to suit a special mission. As the JUPITER prototype version was approached, the first 10 such missiles would be assembled at Redstone, too. Afterwards, through prototype number 18, the contractor would assemble the odd-numbered vehicles and Redstone the even-numbered, and this would continue at The rate of two per month to the end of a 50-missile program. Contractor-produced missiles would be subjected to final modifications and testing (static and otherwise), and instrumented according to the R&D needs at the Arsenal. ABMA envisioned that the first production missiles would be ready for field troops by June 1960 or earlier. Funding estimates were $43 million for FY 1956 and $96.52 million for FY 1957, with a total program cost estimated at $452.21 million. The accomplishment of the development goal, according to ABMA’s belief, would depend on the resolution of two major problem areas. These were engines and range facilities. Four ballistic missile programs were largely dependent on NAA’ s 150,000-pound-thrust engine production, and Army negotiators were experiencing difficulty obtaining Western Development Division approval on delivery dates to meet the Army-Navy IRBM development schedule. The second problem related to range facilities at Patrick Air Force Base, especially the Cape Canaveral complex. It appeared to ABMA that DOD would have to make a thorough study of capabilities and requirements of this installation through l960. DOD reacted quickly to the presentation and, on 15 December 1955, the development plan was tentatively approved, that is, subject to some limitations and until better data were available. One of the qualifications pertained to the guidance and control (G&C) development. The Army, in the plan, proposed that a radio-inertial guidance scheme be developed as backup for the all-inertial guidance system, and DOD felt that the system proposed for the Air Force might be considered as the alternate method. Additionally, DOD believed that the solid propellant program, which was scheduled for eventual submarine employment, should be coordinated with the Air Force. In fact, they went on to say there should be a tri-service position on such development. Relative to the engine problem, OSD-BMC had learned that the missile developers of the three services were studying the problem, and they had requested a report on this matter from the Air Force by mid-January 1956. On Patrick facilities, a master plan and test schedule for all programs was requested to be ready for submission in April 1956. Funds in the amount of $50.8 million for FY 1956 and $111.1 million for FY 1957 were approved and, in addition, funds for the tactical REDSTONE program could be used to expedite IRBM development. And lastly, OSDBMC desired that a monthly progress report be submitted covering component development, rocket engine supply, flight test, and other items of importance. Major problem areas covered in the tentative November plans began to be resolved, in part, by January 1956. During that month General Medaris met with General Schriever of WDD and came to an agreement on the allocation of NAA motors to ABMA. Also within the month, emergency construction was started at the Cape in support of the missile flight testing programs. Although progress had been made by concluding the engine agreement, ABMA was not satisfied with the situation as it applied then or would apply in the succeeding years. WDD had allocation control from the NAA source, and ABMA felt that it needed direct contractual relationship in order for an engine to be produced that would meet the needs of the JUPITER system. General Medaris expressed these feelings to General Schriever, and the latter replied that he did not foresee any difficulty in the procurement of engines for the JUPITER program through a military interdepartmental procurement request (MIPR) to WDD. General Schriever went on to say that he would extend every consideration possible, "short of those which might engender delays in the ICBM and IRBM programs." The qualifying phrase bothered ABMA, for it appeared to say that JUPITER had a second rather than equal priority to the other IRBM. This was not the only item that ABMA was unsatisfied with, as the only contractors (NAA and Aerojet General) for powerful thrust engines had their capabilities saturated with requirements to fill orders for the four major ballistic missile programs. In other words, the opportunity for research was small, and ABMA felt that NAA’s engine was only marginal for the JUPITER program. Be that as it may, this was the situation ABMA faced in 1956. In getting the Army-Navy program under way, operational priority goals were established. The first was to comply with the DOD directive to design a basic missile that was responsive to land and sea requirements. A second represented the desires of DOD and the State Department, and that was the demonstration of the capability to fire a ballistic missile to a range greater than 1,000 nautical miles. From first appearances, it seemed that parallel development was the obvious course to follow, but the Army and Navy soon realized that there were not enough technically qualified personnel available to pursue this dual program. In fact, they aligned their program to the basic design, an early operational capability, and, then, the long-range shot. As a note of interest, on 20 September 1956, a JUPITER C attained an altitude of 682 statue miles and a range of 3,335 statue miles, shattering all existing records at that time in both categories. This flight admirably satisfied DOD and State Department requirements. One of the first orders of business, after the February 1956 activation, was to update the development. Several substantial changes were made. For example, in November 1955, it had been planned to start with a 65-foot missile and, then, gradually reduce the length, but the Navy requested that the missile be as short as possible. So the previous plan was abandoned, and the development program was to aim for a 55-foot missile with a 105-inch diameter (10 inches greater than had been planned). At the outset the Army believed the range capability for such a system would be about 1,300 nautical miles with a growth potential to 1,400. Subsequently, the length was specified for 58 feet to assure the 1,500-mile range. Plans were also becoming firm on developing other components of the missile. In the G&C section, the all-inertial system appeared to offer the best approach, but there were some problems to be considered. To achieve an accuracy of a 1,500-meter miss distance circular probable error (CPE) at full range, fuel cutoff had to be effected within close limits. However, there were a number of these that could be resolved and proven through testing. For the Navy, investigations were in progress to determine if the SINS could be connected to the inertial guidance system. In any event, ABMA felt that a parallel program to develop radio-inertial guidance was a must to assure that there was an adequate system when the missile was operational. This could be accomplished through the coded doppler radar command (CODORAC) system, in which considerable development progress had already been recorded. The re-entry problem was being studied, too, and plans were made as to the methods of conducting tests. ABMA was developing a three-stage vehicle with a detachable head that would approximate conditions of the JUPITER upon re-entry. Twelve vehicles designated as composite re-entry test missiles (CRTM) were allocated to this phase of the program. The REDSTONE and a cluster of scaled-down SERGEANT motors served as the booster element. According to the plan, ABMA was still dissatisfied with the engine arrangements. It was pointed out that all work was proceeding on known and proven designs, whereas they felt that some engineering efforts should be devoted to development of higher-thrust engines. ABMA also mentioned that it planned to investigate different fuels, oxidizers, and additives that might afford greater efficiency and reduce logistic problems. Basically, It was requested that an additional contractor be phased into the engine program. OSD-BMC reviewed the plan, and took several actions. For example, they disapproved the introduction of a new engine contractor; however, it was noted there were modifications that could be made to the NAA and Aerojet engines to improve performance. Moreover, the idea of forward research was not shelved, as DOD had directed its R&D element to make a study on future requirements for higher-thrust engines, and ABMA was told to proceed with its liquid propellant research studies. On another important matter- -the radio inertial guidance system backup program—OSD-BMC noted that such development was contingent on construction of an engineering facility at JPL. Funds were approved for buying contractor equipment and training equipment, but FY 1957 MCA construction fund approval was deferred pending a complete review. In all cases, ABMA was cautioned to maintain close coordination with the Air Force so as to assure joint development of items common to the IRBMs. Navy Requirements in the Development Program When the Army and Navy actually began the development program, there were a number of problems to overcome. These stemmed mainly from the reconciliation of requirements for the two services into a single missile. Each had to provide for certain operational peculiarities. In this respect, whereas the Army could handle a rather lengthy weapon, the Navy required a weapon as short as possible. The original Army proposal was for a missile that was better than 90 feet high, and the Navy aimed for a 50-foot missile. This called for a compromise, and a 58-foot weapon was decided upon. By going to the shorter length, a greater diameter had to be invoked--105 inches—which caused some Army concern for logistics and transportation reasons. Compromise between the two to gain respective goals became the key to the development mode. In reality, Navy requirements played a rather heavy role in the system’s design characteristics in view of the peculiarities of launching a missile at sea: safety and adequate engineering for ship conversion. It was necessary to design a complete set of launching and handling equipment for sea use as well as a set for the land version of the missile. In all of these cases, technical coordination was required and the decisions influenced configuration, so really ABMA was engrossed in satisfying all requirements. General Medaris, in November 1956, estimated that the decision on the length and diameter caused a design time loss of two months, and another two-month loss to define several other Navy requirements. Yet, it was known that the sea-based missile would be more complex than the land-based, for many of the latter’s requirements had been resolved and proven. Although the Army people realized that the integration of Navy requirements would incur some delay, nevertheless they knew that if these complex sea-based problems were not resolved, an unacceptable delay of shipboard application would occur. So, to gain Army goals in the long run, Navy problems were tackled, and by 1 September 1956 the over-all program was well adjusted and had a promise of being able to fire the first JUPITER-configured missile in January or February 1957. This was three months in advance of the original schedule. It was a strange turn of events, that during the first nine months of 1956 Army personnel were working on problems in navigation, ship motion, missile guidance, launching and handling, submarine application, and fuzing requirements. The Navy contributed its part, as well, especially in the nose cone recovery program. In this respect, they furnished a dummy missile under naval contract, and loaned a considerable amount of equipment to the program. Withdrawal from Army Program The Navy was never particularly satisfied with a liquid-propelled IRBM because of the storage, handling, and launching problems involved. Inherently, liquid-propelled missiles, after ignition, rise from the launch ring much slower than solid propellant counterparts whose lift-off is nearly simultaneous with the firing command. Knowing these facts, the Navy sought very early to get a solid propellant version of the IRBM approved. On 20 March 1956, OSD-BMC began to consider the proposal, and early the next month the decision was forthcoming. The Navy was allowed to do a systems study to include component development. This could involve propulsion flight testing as an aid toward determining weapon system feasibility. When the studies were completed and if the development work showed promise, OSD-BMC wanted a full-scale review before a missile development program was initiated. As the Navy progressed in its solid propellant study, they became more and more removed from adapting the JUPITER to shipboard application, for a shorter missile was their desire. This meant a separate weapon system development, so in cooperation with the Lockheed Missile Division, a study was started toward such aims. One of the critical factors to be considered in making the decision, from the standpoint of DOD and the President, was tether or not a 1 half year delay for the operational date could be accepted. Secretary Wilson’s decision on the course of Navy IRBM development was made on 8 December 1956. At that time the Navy was authorized to delete from its program the liquid-propelled JUPITER, and to proceed with the development of the POLARIS IRBM with submarine application as first priority. This action, of course, prompted the dissolution of the JANBMC and the formation of the Army Ballistic Missile Committee (ABMC) with the Secretary of Army serving as chairman. Withdrawal by the Navy from the Army program was not simultaneous, for there were many areas where the two services bad common interests. In fact, the Navy mentioned several, especially in the nose cone recovery efforts. Moreover, Navy Special Project Office asked its office at ABMA to determine the extent that the Army could participate in the POLARIS program, particularly nose cone and G&C. For these reasons, a Navy Liaison Office was maintained at the Army agency, but for all practical purposes the Navy was severed from the Army program. Departure of the Navy placed the Army IRBM program in a precarious position, for, coupled with the Secretary’s decision in this respect, his roles and mission statement of November presented a situation wherein the Army was developing a missile that it could not employ. Douglas Aircraft Company was already in the process of developing the SM-75 THOR for the Air Force, and in December 1956 there was uncertainty as to whether or not the Air Force wanted another IRBM. The Army’s in-house development prospects in early 1957 did not appear ‘bright." |

|

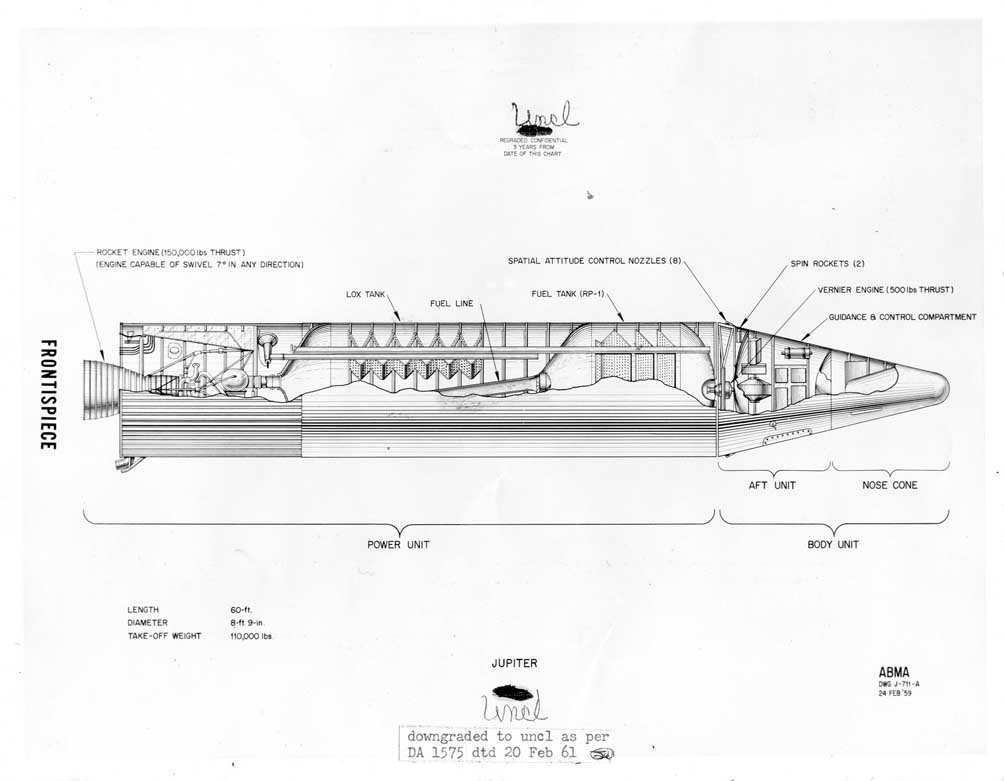

As to other missile vital statistics, the JUPITER was a single-stage, liquid-propelled, rocket-powered ballistic missile, designed to carry a 1,600-pound payload to a maximum range of 1,500 nautical miles, with a 1,500-meter circular probable error (CPE). It was composed of three major assemblies: the nose cone, the aft unit with instrument group, and the thrust unit. Structural loads were divided between the missile skin and a number of Z-ring stiffeners. The ablative heat-protected nose cone contained the warhead, fusing and arming device, and related power equipment. G&C was housed in the aft unit, with the exception of such components as the swiveling actuators for the main rocket engine. Vernier engine spin rockets and jet nozzles for spatial attitude control were also located in the aft unit. When the nose cone and aft unit were joined, it became the missile body. The thrust unit was made up of a center unit containing the propellant tanks and feed lines, the rocket engine, and the tail section. The tail section also contained cabling and propulsion system accessories. |

|

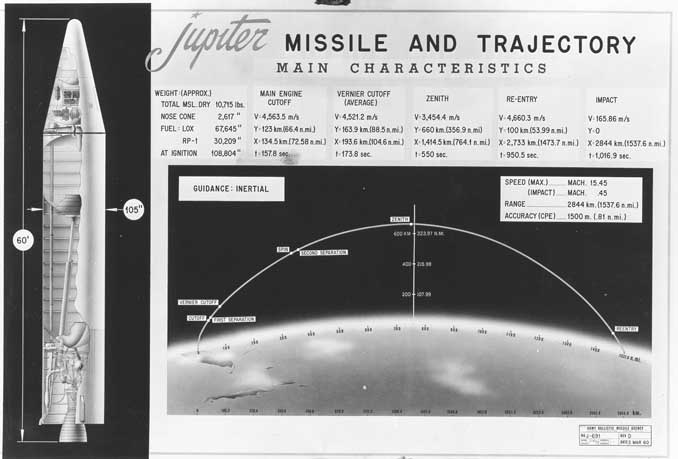

Besides serving as the thrust agent for the missile, propellants were also important in missile control. For example, the thrust unit effected roll control by deflecting the exhaust gases from the turbine and swiveling the turbine exhaust nozzle. A second unit was the vernier thrust system that was mounted on the aft section of the body to provide fine control of cutoff velocity of the body immediately after separation from the thrust unit. This was accomplished by a solid propellant unit rated at 500 pounds of thrust and capable of operating for 20 seconds. While the missile was out of the sensible atmosphere and had already separated from its thrust unit, eight jet nozzles equally spaced on the missile body provided pitch, yaw, and roll. These jets were off-on types, and were powered by nitrogen from storage bottles housed in the body. This formed the spatial attitude control system. To depict the operation of the propulsion system during a typical flight, the missile was launched vertically and then was tilted gradually by g guidance program device into a ballistic trajectory. Trajectory was divided into four major phases: main power, vernier, spatial attitude control, and re-entry. While in the main power phase, the missile was controlled in pitch and yaw by hydraulically activated swiveling of the rocket engine and in roll by the thrust unit roll control system. Separation of the body and thrust unit then occurred when the main rocket engine cut off, and then the missile was in its vernier phase. The vernier engine now operated to control missile velocity along the trajectory until the slant range computer in the G&C was satisfied. All during this time, the spatial attitude nozzles were helping maintain control, and were especially preparing for the re-entry phase. When the correct attitude was achieved, two spin rockets at the base of the body were activated to impart a 60-rpm rotation to the body, and, upon attaining this rate, nose cone separation occurred. No controls were exercised on the nose cone after separation because of the high Mach re-entry speed. G&C was accomplished by an all-inertial system that was based on the principle of constraining the missile as closely as possible along a precalculated standard trajectory. This work was done by a null-seeking system that continuously compared actual experience data with that which had been precalculated. Then, attempts were made to eliminate the errors by gimballing the engine and signaling the main and vernier cutoffs at the appropriate times. Total flight time for the JUPITER for a maximum range firing was 1,016.9 seconds. At the end of 70 seconds from lift-off, the missile experienced its maximum dynamic pressure (13.69 G’s) during the rise, and main engine cutoff occurred at the end of 157.8 seconds at a speed of Mach 13.04. Separation of the thrust unit and the vernier start happened at 161.8 seconds, and vernier cutoff was at 173.8 seconds. Nose cone separation occurred at 339.3 seconds, and the nose cone reached its zenith at 552 seconds. Re-entry began at 950 seconds (Mach 15.45) at about 100 km’s in height, and maximum dynamic pressure (44 0’s) during the descent was exerted at 980 seconds. Then, impact occurred at the previously cited 1,016.9 seconds when the aerodynamic drag had reduced the speed to Mach .49. After the mobility operational concept was deleted, the mode of employment was from static sites. A continuous capability to salvo all 15 missiles allocated to a squadron within 15 minutes after receipt of the execution order was to be maintained. This meant that the missile had to be in a 15-minute readiness condition at all times. Squadrons would deploy around a single support base on five outlying launching positions. Each launch position would contain three emplacements, comprised of three missiles, three launchers, and one triple launch control trailer (LCT). This became known as the three-by-five configuration. No alternate positions were provided, and no tactical movement of launch positions was planned. Development Program Nose Cone As earlier mentioned, nose cone re-entry into the sensible atmosphere was recognized by ABMA at the beginning of its operations as a difficult technical problem to resolve, so this task was undertaken immediately. From German rocket history, ABMA scientists knew that, from a height of 107 miles, re-entry thermal heat was such that melting would occur. After the war, high altitude probes at WSMR met with these conditions. When the JUPITER was approved, the developers knew that missile ranges in excess of 250 miles would meet with this re-entry factor. Since the JUPITER was to be a 1,500-mile weapon system, tie problem was compounded because of the higher Mach rate needed to reach the increased distance. At that range, steel would have been easily melted in the thermal barrier. ABMA initially began work by screening potential materials and methods, and testing these materials with jet burners. From this, they chose what seemed the best. Four protective methods were explored: ablation, heat sink, radiation, and transpiration. Ablation proved promising, so an investigation of plastics, fibers, and ceramics was started. To flight test the findings, three scaled-down models were constructed, and the first was flown on the IRBM demonstration flight in September 1956. No recovery attempts were made, but, according to telemetry data, the model functioned well. Recovery efforts were scheduled for the Missile Number 34 shot in May 1957; however, the mission was not fulfilled because the REDSTONE booster failed. Missile Number 40, fired in August, was completely successful, and the nose cone was recovered close to the predicted impact range of 1,100 NAA. Other shots were unnecessary, and the scaled-model tests were concluded. The ablation principle had been proven. ABMA now began to work toward the full-scale nose cone re-entry. Missile AM-5 launched on 18 May 1958 registered a re-entry success. Recovery of the full-scale nose cone in good condition by the Navy marked a significant step forward in the state-of-the-art of this nation’s long-range missile development programs. Also interesting was the fact that re-entry was visible to on-site observers. This was followed by a July firing—Missile AM-6—and recovery. The most famous of the re-entry tests, however, was JUPITER Missile AM-18 fired on 18 May 1959. Contained within the nose cone were two primates, designated Able and Baker, that survived their flight in excellent condition. Thus, not only was ABMA’s ablative theory ably demonstrated, but life could pass through outer space and be safely brought back to the earth. Re-entry could have posed a problem from another standpoint—aerodynamic stability—but fortunately no difficulties appeared. Configuration was responsible for this successful development. As to the vital details, the nose cone had a 12.5-inch radius spherical tip joined to a cone frustum of 65-inch base diameter, with an over-all length of nine feet. The nose cone also had a rear cover shaped in the form of a shallow-dished (convex outward) bulkhead, and this was the key part to providing aerodynamic stability for any attitude to re-entry. Tests of this configuration were first made in wind tunnels; then, on the scale re-entry models; and, finally, on the full-scale JUPITER. Thus, from re-entry to impact, the nose cone was a stable component. Guidance and Control At the outset of the JUPITER development program, two G&C schemes were under consideration: the all-inertial guidance system and the radio-inertial guidance system, with the latter being considered as the alternate or back-up means. Subsequently, in 1958, the radioinertial part of the program was canceled, for development efforts in the all-inertial area had progressed systematically and successfully. Thus, although ABMA and JPL did laboratory work on the radio-inertial system from September 1957 until its cancellation, principal attention will be devoted to all-inertial development. The JUPITER all-inertial guidance system development program was based heavily on the success of the tried and proven REDSTONE G&C system. From the beginning, this move appeared to be logical as the best means to meet such multiple requirements as simplicity, reliability, mobility, jamming resistance, and availability of components. Work assigned to this system involved constraining the system along a ballistic trajectory from liftoff to impact, and the principal component that performed this function vas the gyro-stabilized platform (ST-90). Important to and located on the ST-90 were three air-bearing supported accelerometers that measured acceleration on the missile in three directions. Primarily, these were needed to detect and act on external forces that might influence the trajectory. To some extent, certain forces such as standard thrust of the propulsion system, aerodynamic drag, and separation forces could be determined before firing, and, if the missile had only these to contend with, the trajectory would be standard and the G&C problem simple. But non-standard forces, which were quite unpredictable from either points in time or space, did exist and some means had to be available to start a proper reaction. Examples of the non-standard type include wind gusts and deviations in thrust. Thus, the problem at hand, when occasioned by these external forces, was to bring the missile from its actual trajectory to that desired in order to assure a CPE of not greater than 1,500 meters. Since guidance was not feasible during the re-entry phase, these problems had to be solved before nose cone separation. There were also several other major components that made up a part of the G&C system. One of these was the guidance computer, which was packaged outside the ST-90 because of weight. This unit received its input from a gyro accelerometer, and was concerned with distance and speed information. A programming device was responsible for tilting the missile in pitch and compensating for environmental conditions experienced during the trajectory. All information was then fed into the control computer—attitude information from the ST-90, angle-of-attack signals from the angle-of-attack meter, and guidance signals from the guidance computer—which assimilated the information and signaled the hydraulic actuators for such actions as swiveling the main and vernier engines or operation of the jet nozzles. The target date to accomplish firm G&C plans was November 1956, and this was met. Specifications were furnished to the Ford Instrument Company for the delivery of the ST-90 in January 1957. A testing program was then under way until October 1957, when JUPITER Missile 3 was used to flight-test the ST-90 and related components. It worked. Propulsion System Perhaps one of the most difficult of the development problems to resolve was in the propulsion area, an item over which ABMA had the least control. The heart of the system was the main engine, a component commercially produced by NAA. As earlier mentioned, the supply source was saturated in satisfying the demands of four long-range missile systems. Since the Air Force was in charge of the development of three, ABMA’s requirements had considerable difficulty in being met. Also, ABMA thought that the NAA engine was only marginal in satisfying JUPITER needs, yet there was little opportunity for NAA to enter into a large-scale research program. To ABMA’s way of thinking, the over-all engine program should involve one in production, one in development, and one in advanced design and component developments. Although DOD people were studying long-range needs for new and higher thrust rated engines, this did not solve ABMA’s problem of the moment. This meant that ABMA had to "make do" with the then present NAA engine and suggest modifications to suit the JUPITER missile. Modifications included such items as thrust governing and throttling. As to the method of propulsion system operation, the main 150,000-pound-thrust engine used LOX and kerosene. The thrust chamber was of tubular wall-type construction, with a self-impinging fuel injector and a regenerative cooling system. Gimballing the engine, which was coupled to hydraulic actuators, permitted missile control in pitch and yaw. There were several engine subsystems. One of these was the propellant feed system that delivered the propellant from the tanks to the thrust unit by means of valves and a turbopump. Also, the propulsion contained a lube oil system to lubricate the moving parts. A pneumatic pressure system was used to operate the valves, and a hydraulic system operated the gimballing unit. In the first stages of development, the vernier engine of the propulsion system was fueled mainly with hydrogen peroxide—90 per cent—and a 10 per cent catalyst; but, starting with the firing of JUPITER AM -7 on 27 August 1958, a solid propellant engine was adopted. The vernier unit consisted of an engine case that housed the propellant and served as the combustion chamber, a pyrogen unit for engine ignition, a nozzle, and a thrust termination device. Unlike the main engine, all components formed one unit. In operation, the vernier engine ignited two seconds after separation from the main thrust unit. The vernier unit then propelled the missile body until the desired velocity was attained, and when this requirement was satisfied, cutoff occurred. Squibs were used for the thrust termination device, and the engine nozzle was blown away. Although the two foregoing units were the major portion of the propulsion system, other devices, already discussed in part, were equally important in solving the target range problem. These included a missile roll control system, and a spatial attitude control system. NAA delivered its first nonflyable main engine to ABMA in July 1956, and the Agency began a static test program in September. At first, the tests progressed smoothly with a number of static firings lasting for several seconds; but, by November, four thrust chambers had burned out, causing delay while ABMA and NAA were investigating the problem. Strengthening modifications to the thrust chamber eliminated the difficulty, and in January 1957 the static testing program was progressing satisfactorily. ABMA received its first flyable engine in September 1956; and, during inspection, a number of design deficiencies were noted. Within a short time—November—the second engine was delivered. Both of the engines were down rated by ABMA from 150,000 pounds to 135,000 pounds because the turbopump was not satisfactory. NAA was already in the process of modifying this unit, and two pumps were subjected to prolonged tests with satisfactory results. However, because of the critical supply of these engines, the first JUPITER missiles had to fly with the lower thrust units. In fact, while procuring the first four flyable units, the situation was far from being satisfactory to ABMA. For one thing, procurement had to be effected through WDD, which caused an undue administrative workload. Then, the uncovering of the technical design deficiencies created a severe problem in assuring the timely delivery of spare parts and modification kits. One problem had, in turn, created another. NAA was supposed to have been able to ship the missiles completely modified to ABMA in January 1957, but it was several months after that. Engine modifications of late 1956 and 1957, however, appeared to be quite successful. This was aptly demonstrated in one instance during a static test at NAA, when an unintended overrun to 195,000 pounds of thrust happened. The turbopump and the thrust chamber did not show any damage. From time to time, however, technical problems, including the turbopump, did crop up. Another major propulsion system problem concerned propellant sloshing. This condition was uncovered during the firing of JUPITER 1B, the second JUPITER missile fired. After a normal liftoff and up to 70 seconds, the flight program was normal, but then oscillations in pitch and yaw began to build up and the missile disintegrated at 43 seconds. Heavy instrumentation immediately located the difficulty, and data showed that propellant sloshing was caused by the tilting program to such a degree that the missile became dynamically unstable. A rather ingenious testing device was rigged by ABMA in the attempt to cope with the sloshing problem. A JUPITER center section was placed on a railroad flat car, with proper attachments that would simulate flight environment forces on the propellant tanks, and several types of baffles were placed inside the tanks as a means to reduce the sloshing. Success was attained by installing a turncated-cone type in the fuel tank and an accordion type in the LOX tank. The full-scale IRBM flight of JUPITER 1 in May 1957 aptly demonstrated two major points: (1) quick reaction of an in-house R&D team and the resulting brevity in time between problem isolation and component fix, and (2) the validity of heavily instrumented R&D flights. The above represented the major problem areas in the propulsion system development program. This is not to say that problems of the moment were not experienced with other components. For example, during the early flights of the solid propellant vernier engine, some failures did occur, but quite often it was hard to tell whether or not the difficulty had been caused by main engine failures. In any event, development progress was not deterred by the other propulsion components, which never became major problem areas. |

|

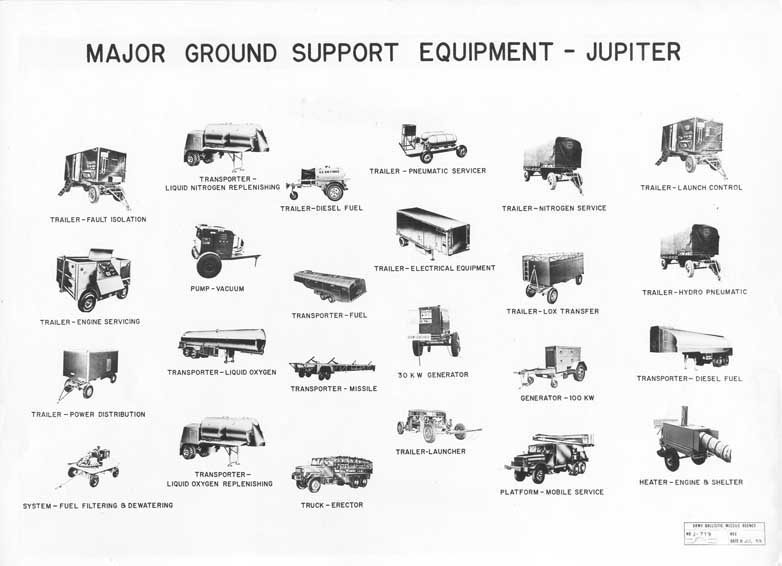

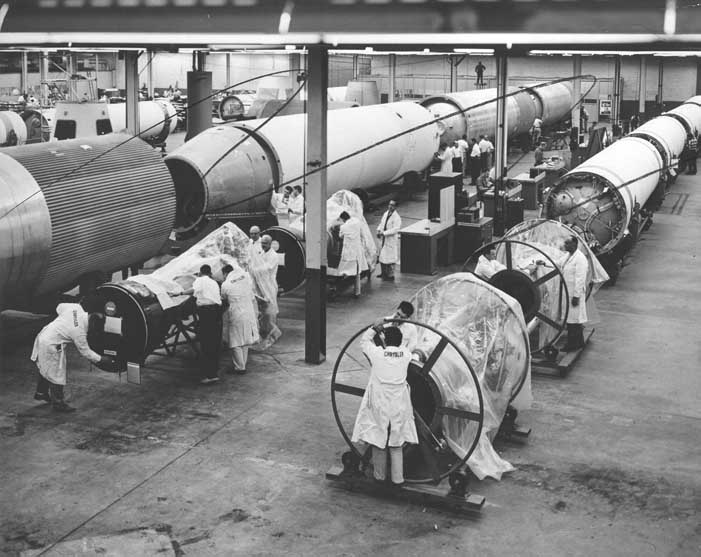

This was not the end of the complications, either. For one thing, the employment concept changed. To attain the early operational capability, the Air Force went along with the Army idea of mobility, as opposed to the fixed site operation they supported. ABMA immediately went to work on mobile OSE, which was not too difficult because they had REDSTONE equipment to serve as a pattern. The main problem in the mobility phase was expediting contractor delivery, for, more often than not, reports constantly cited that such-and-such a component was late in delivery. This caused concern as the deployment date was rapidly approaching. Added to this, the mobility concept was deleted in November 1958. Some of the tension was relaxed, however, for by that time it was realized that the necessary agreements would not be signed in time for the December employment. This afforded an opportunity for equipment refinement and matching and mating work. On the other hand, this stretch-out indicated that measures would have to be taken to adequately store missiles and equipment until the agreement was consummated. Mention has been made of the fact that ABMA technical experts considered JUPITER GSE to be one year behind. In some respects, the problem was not as adverse as this connotes. For example, from the outset of the program, ABMA made a concerted effort to fabricate its R&D RSE in a design that would be suitable for tactical employment. This pattern held true with the launcher, transport equipment, and other JUPITER peculiar GSE components. With the in-house design and fabrication, necessary changes manifested during the R&D firing program could be integrated with ease, and each change moved the equipment nearer to the tactical configuration. During this systematic hardware buildup, it was also possible to design suitable checkout gear. Perhaps one of the most important assets during the GSE buildup phase was the on-hand experience in other large ballistic missile programs. Drawing on this experience, equipment was simplified. In this way, complex and expensive hydraulic erection was rejected for the better lightweight mode; a ring-type launcher was used rather than the more complicated fall-away leg type; and an inexpensive one-time use cryogenic cooler was selected over an expensive electric cooler for use in the countdown phase. By April 1958, the first tactical type launcher had been completed and successfully tested with the lightweight erection equipment (primarily a long boom and cables). Shortly after that came R&D prototype items such as the launcher auxiliary rings, hydro-pneumatic trailer, azimuth laying equipment, intra-squadron communication equipment, supervisory control system, missile transporter, launcher transporter, LOX transfer trailer, propulsion components tester, and other related items of equipment involving both the physical handling and testing of the missile. At the Design Engineering Inspection held on 7-10 October 1958, the GSE performed well and demonstrated that the JUPITER system could meet the 15-minute countdown-to-liftoff sequence. Progress in the GSE field was far from systematic, though. Basically, the problem was delivery of the tactical item by the manufacturer after the prototype had been submitted by ABMA for fabrication. Also, the Air Force had submitted more than 70 alteration requests, which, in part, may have caused some of the manufacturing difficulties. Then, in November 1958, the mobility factor was deleted from the JUPITER program. This meant there would be a triple launch control trailer (LCT), as opposed to the single LCT that was necessary in a mobile weapon system. Additionally, this action eliminated the cable and launcher transporters. Together, all of these actions could have delayed the deployment of the system until reorientation plans could have been completed, but the lack of agreement with the host country, in the long run, provided ample time. Production and Delivery As may be surmised, production plans for the JUPITER program were as changeable as all other facets of operation. In the beginning, a 50-missile test program was planned involving a composite of JUPITER C’s for re-entry vehicle tests, JUPITER A’s for component testing, and the JUPITER configured missile. During this time, ABMA was involved in a production schedule of about two missiles per month. The roles and missions statement of November 1956 posed the initial threat to the program, and the withdrawal of the Navy in January 1957 further placed the program in a precarious position. However, it was August 1957 before the Secretary of Defense directed that the production schedule be limited to one missile per month, pending a decision as to the IRBM that would be selected for weaponization. The Secretary’s decision was in effect for only a short time, for in October 1957 weaponization of the THOR and the JUPITER was directed. In turn, this released the production schedule to the two missiles per month immediately, and, on 27 November, notice was received that production was to be held to a maximum of five JUPITER missiles per month. Briefly, the total program, that is, R&D and IOC, was set at 125 missiles. After that, for one reason or another, adjustments were made upwards and downwards. During most of FY 1958, that is, after the program was refined subsequent to the October 1957 decision, the approved program called for 36 R&D missiles, 62 IOC missiles, ground equipment for three squadrons, and prototype and training equipment. Here, the program had been influenced by the budgetary cut first evidenced in August 1958 and the reduction from four JUPITER squadrons to three the following October. This was not the end, for budgetary cuts in December 1958 again reduced the program when five of the R&D missiles were deleted. At that time, the allocation line-up included 11 R&D, 20 reliability and product improvement, and 62 IOC. During the latter half of 1959, another missile was removed, which left the total program figure at 92. From there, the figure went to 93, and finally 94. Fifty-nine GSE sets made up the 25 total program in that respect. Deliveries of the IOC missiles to the Air Force began on 28 August 1958, and, at that time, 31 other JUPITER missiles were in various stages of fabrication at the Michigan Ordnance Missile Plant and ABMA. From August until November 1958, ABMA continuously reported that sufficient IOC missiles would be ready to meet the December deployment date of the first squadron. However, the lack of a firm agreement with the host country caused DOD to direct a delivery stretch-out. In this case, money could be saved, as the necessity for contractor overtime was considerably reduced. Also, the opportunity was presented to iron out technical difficulties that had arisen in the NAA propulsion system. When the agreements with NATO I were concluded in August 1959 with an operational readiness date of 1 May 1960, there was ample time to deliver required missiles by the cheaper surface shipment rather than the expensive air shipment that had been planned for the December 1958 deployment. By the time the agreements with NATO II had been concluded, the total production program was ready for delivery. Missile Testing Program One of the more amazing factors in the JUPITER development program was the small amount of time that elapsed between program approval and the actual flight testing of a missile that resembled the final tactical configuration—November 1955 until March 1957. By comparison, the time frame was even more compressed than the REDSTONE program—July 1950 to August 1953—but this system was the key to the JUPITER success story. In many respects, JUPITER components were product improvements of REDSTONE counterparts. During the previously-mentioned missile study years of 1954 and 1955, the Redstone Arsenal group had made wind tunnel tests of model missiles of every conceivable shape and form. Added to this, they had the flight analysis of the REDSTONEs. So when the JUPITER requirement came along, they knew what configurations would fly. Even the forced reduction in length had no ill effects on the flight behavior pattern. Components within the shell followed the same "building block" formula. For example, the angle-of-attack indicator program dated back to 1952, and experience in this work was important in view of the lack of control of the re-entry body. Speaking of the nose cone, even this configuration was solved within six months of program inception, and the protective means by way of ablation was solved in nine months. Practically every part of the missile had undergone an exhaustive testing program; and, thus, the JUPITER development phase was a refinement to meet the IRBM requirements. As a result, the JUPITER could have been fired in anger in 1958, and possibly in 1957—two years, more or less, after program approval. The actual flight testing in support of JUPITER development was divided into three phases. Two of these used the REDSTONE as the flight test vehicle to prove out JUPITER components. Designated as JUPITER A’s, 25 missiles were fired between September 1955 and June 1958. Objectives of these tests were to obtain design criteria, apply the angle-of-attack meter to the IRBM, evolve separation procedures, prove guidance system accuracy, and design and prove propulsion system thrust control. To solve the re-entry problem, three missiles designated as JUPITER C’s were flown. As to the tally, 20 of the 25 JUPITER A’s were rated as mission achieved, two registered partial successes, and three were considered to be unsuccessful. All three of the JUPITER C’s performed well. On the second firing, an attempt was made to recover the nose cone, and this failed. However, on the third and last re-entry test, the nose cone was recovered. Success was such that it was no longer necessary to continue this phase of the program, as one of the tests had ably proven the theory of long-range missile flight and the other had demonstrated that the re-entry body could be brought from space into the sensible atmosphere without disintegrating. At the outset of the JUPITER program, it was planned to fire the first JUPITER-configured missile in May of 1957, but the success registered by the JUPITER A’s and C’s formed the belief that two assurance missiles could be fired before the scheduled date. As it turned out, it was well this decision was made, for JUPITER lA had a tail-heating problem and lB had a propellant sloshing problem. These were solved and the May firing of JUPITER 1 gave the Western World its first demonstrated IRBM. Two successive firings registered in the success box, but Missile 3A met with the previously mentioned turbopump problem. This difficulty continued with Missile 4; however, the system was back on the success trail with the firing of Missile 5. This event marked the recovery of the first full-scale re-entry body. All in all, the JUPITER R&D firing program was quite successful. Twenty-two were rated successful, five were partially successful, and only two were failures, for a total of 29 missiles. Also of significant note, 19 of the 29 were tactical prototypes and 16 of this group impacted within a CPE of 0.81 nautical miles. After the closeout of the R&D firing program in February 1960, five JUPITER missiles were fired. One of these was termed a live systems test in which the missile was successfully fired under conditions approaching the tactical situation. The other four firings were designated as combat training launches (CTL) to promote proficiency and confidence of the NATO troops. Three of these firings were successful and one was partially successful. Eight other CTL firings were still scheduled as of 30 June 1962. Funding As might be suspected, the status of funds for the JUPITER program varied with the fortunes existing at a particular point in time. This covered the range from acceleration to the threat of program cancellation. At the outset, $l0.720 million was allocated for R&D and $23 million for procurement and production (P&P) in support of the development program. Prior to the beginning of FY 1957, plans called for $25 million R&D, $ll.534 million P&P, and a $25 million MCA program. These funds were approved in September 1956, but at the same time, a statutory fiscal limitation was placed against the JUPITER program retroactive to 1 July. Compliance with this directive was almost an impossibility, as 20,000 documents had already been processed with installations throughout the country. ABMA immediately interposed a reclama to this directive, but it was January 1957 before the restriction was lifted. Two events discussed earlier in the study—the Navy pull-out and the DOD decision on roles and missions—caused further adverse action in JUPITER funding. The Air Force had no particular interest in being involved in the development of a second IRBM, and by mid-1957 the Secretary of Defense was becoming more and more of the opinion that only one IRBM was needed. This turn of events had an immediate impact on the ABMA program. Allocations for certain portions of the FY 1957 MCA program were withheld, and the FY 1958 development program was pegged at $35 million to run through November 1957. October world events and recommendations by the ad hoc committee that both IRBM’s be developed brought changes. The approved figure in January 1958 for FY 1958 funds stood at $360.35 million. Of this amount, $230.97 million was to cover IOC procurement and production, but OSD-BMC withdrew the amount the next month pending an agreement by the Army and Air Force on reimbursement. Subsequently, the FY 1958 IOC P&P was placed at $202.70 million. As for the FY 1957 MCA, construction was resumed in January 1958. Some portions of this program, such as construction of a nose cone assembly and checkout facility, had been static since May l957. FY 1959 funds experienced roughly the same pattern as the two preceding fiscal years. The Army planned program reflected a figure of almost $300 million; but, in July 1958, the Air Force made a move to scale the program down to three squadrons and remove all mobility requirements. This did not become a cold fact until October and, thus, funds were committed that were not recoverable. The Air Force figures were placed at $225 million, but the final amount was about $229 million. Besides the impact on the over-all program, this action represented but another example of the difficulty that ABMA fiscal planners experienced. The scaling down of funds also continued during Fiscal Years 1960 and l961. |

|