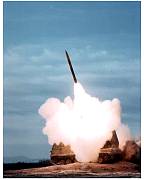

The Multiple Launch Rocket System (MLRS), formerly known as the General Support Rocket System (GSRS), is designed to supplement cannon weapons available to U.S. Army division and corps commanders for the delivery of a large volume of firepower in a very short time against critical, time-sensitive targets. MLRS is a free-flight artillery rocket system that greatly improves the conventional, indirect fire capability of the field Army. The system provides counterbattery fire and suppression of enemy air defenses, light materiel, and personnel targets.

The M270 launcher, a derivative of the Bradley Fighting Vehicle (BFV), carries 12 rockets which it is capable of firing one at a time or in rapid ripples to ranges of more than 30 kilometers. The MLRS rocket is 13 feet long and 9 inches in diameter. MLRS employs the "shoot and scoot" principle to limit vulnerability to counterbattery fire. In addition to the M77 dual purpose conventional submunition equipped with 644 high explosive grenades for anti-personnel and light vehicle engagements, the system can deliver the West German-developed AT2 scatterable mine warhead and has the potential for delivering other warheads. A growth program is under way to add the extended range MLRS (ER-MLRS), which will increase the current range of the basic rocket from 31.8 kilometers (km) to a new range of approximately 50 km. The Guided MLRS (GMLRS), an additional combat support munition, is a modification to further enhance the range and accuracy of the ER-MLRS. The M270 launcher accommodates the MLRS Family of Munitions (MFOM), including the Army Tactical Missile System (Army TACMS). MLRS is co-produced by the United States, Germany, the United Kingdom, France, and Italy.

System Chronology

|

12 December 75 MICOM released a request for proposal (RFP) to industry to assist in determining the best technical approach for the General Support Rocket System. March 76 Firm-fixed-price Concept Definition Study contracts were awarded to Boeing Aerospace Company, Vought Corporation, Martin Marietta Corporation, Emerson Electric Company, and the Northrop Corporation to conduct design and trade-off analyses and system optimization. 14 July 76 The GSRS Project Office was organized on a provisional basis. 14 February 77 In a decision memorandum for the Secretary of the Army, the Secretary of Defense authorized the Army to proceed with the development of the GSRS with an M42 dual purpose submunition warhead. This memorandum also required that the Army address the potential of the GSRS to deliver scatterable mines which included systems existing or under development in other NATO countries. In addition, the Army was required to prepare a plan for terminal homing options in the GSRS program. 16 September 77 Cost-plus-incentive-fee contracts were awarded to Boeing Aerospace Company and the Vought Corporation to design and produce prototypes for competitive evaluation leading to a combined maturation/initial production phase contract for the winner. 1 October 77 The Office of the Project Manager (PM) for GSRS was organized on a permanent basis. 5 December 77 Vought fired its first GSRS test rocket from a fixed tube. 14 April 78 Vought began flight testing the GSRS from a launch pod/container. 30 March 79 Vought launched the first GSRS rocket to be fired out of its "six-pack" launch pod/ container from a Self-Propelled Launcher Loader (SPLL). July 79 The governments of the United States, Germany, France, and the United Kingdom signed a memorandum of understanding (MOU) for joint development and production of GSRS. 16 November 79 GSRS was redesignated MLRS in order to be compatible with the name already established by the European allies. The GSRS Project Office became the MLRS Project Office effective with the redesignation. 29 April 80 The Army announced the selection of the Vought Corporation as the prime contractor for final MLRS system development, which was known as the maturation phase. May 80 A Defense System Acquisition Review Council (DSARC) III decision approved entry of the MLRS program into a maturation phase in which development and low-rate production would be pursued concurrently. This approach differed significantly from traditional acquisition strategy because accelerated design maturity would be accomplished during the validation phase, which preceded the maturation contract award. Immediately following the DSARC III determination, MICOM awarded three separate contracts to the Vought Corporation for completion of the development (maturation) effort, preparation of manufacturing facilities, and initial low-rate MLRS production. 23 July 80 The governments of the United States, the United Kingdom, Germany, and France signed a formal declaration of intent to participate in the concept definition phase of the terminal guidance warhead (TGW) program. The primary mission of the TGW would be to provide rapid fire, non-nuclear capability to destroy a wide spectrum of stationary and moving, medium hard to very hard, armored targets. The declaration required that the TGW be jointly developed, with active participation by industries of all four nations. 7 August 80 The Secretary of Defense approved the Army's recommendation for MLRS to enter the maturation/low-rate production phase with one contractor. 1980 The validation phase test program for MLRS was completed. November 80 Maturation development flight tests of MLRS began at White Sands Missile Range (WSMR). 26 March 81 DA issued a letter of approval establishing the need for an MLRS chemical warhead. 9 September 81 The four countries jointly funding the MLRS development program signed a supplement to the basic MLRS MOU of July 79, providing for the concept definition phase of the TGW program. 10 December 81 Concept/international program definition contracts were awarded to General Dynamics, Hughes Aircraft Company, Martin Marietta, Raytheon, and Great Britain's Hunting Engineering for multinational development of the TGW. 1982 Vought delivered the first seven low-rate production SPLLs. 10 February 82 The first full-load launch of MLRS (12 rockets) inflicted heavy damage to a target array located nearly 10 miles from the launcher. 31 March 82 Vought was awarded a concept definition contract to begin development of a binary chemical warhead (BCW). The BCW would be a retaliatory weapon with a medium range, high volume of fire and wide area coverage. It would force enemy troops to mask, don protective gear, or restrict themselves to protective structures thereby reducing the enemy's ability to move, maneuver, and fight. May 82 The maturation phase flight test program, which began in November 80 at WSMR, was successfully concluded. 19 May 82 Vought Corporation delivered the first six M42 low-rate production rockets (one crated round) from its Camden, Arkansas, facility. 22 May 82 Vought initiated the production qualification test program on MLRS. 29 July 82 An MOU supplement authorizing Italy's participation in the MLRS program was signed by all cooperating nations. 4 February 83 The production qualification test program was successfully completed at WSMR. 31 March 83 The first MLRS tactical battery was fielded at Fort Riley, Kansas, meeting the scheduled initial operational capability (IOC) date. 14 April 83 The Secretary of the Army approved full-scale production of the MLRS. 21 April 83 The Secretary of the Army approved type classification Standard for MLRS major equipment. 1 September 83 The first outside continental United States (OCONUS) MLRS battery was fielded to the 8th Infantry Division (ID) in Germany. 5 December 83 The United States, France, Germany, and the United Kingdom signed an MOU supplement to formally establish a TGW development program. 18 January 84 The first production fly-to-buy (FTB) flight tests of MLRS were conducted at WSMR. 7 February 84 As a result of some MLRS items experiencing higher failure rates than others, the MLRS Project Office Readiness Control Center was established to monitor worldwide SPLL status on a daily basis and to take immediate action to assure supportability of the fielded MLRS. June 84 Fielding of MLRS to the 2d ID in Korea was completed, representing the largest single increase in raw firepower for the Eighth U.S. Army (EUSA) in almost 5 years. 31 August 84 Ling-Timco-Vought (LTV) Aerospace received a contract to conduct a validation phase for the BCW. 28 September 84 DSARC approved the TGW advanced development program. 29 November 84 A cost-plus-incentive-fee contract for the cooperative development of the TGW was awarded to a consortium of companies consisting of the Martin Marietta Corporation of the United States; Thomson Brandt Armaments of France; Thorn EMI Electronics, Limited, of the United Kingdom; and Diehl GmbH and Company of Germany. The remaining participant was MDTT, Incorporated, a U.S. company with a fully integrated U.S.-European staff which acted as a management focal point for the joint venture. 31 January 85 Using the total package/unit materiel fielding (TP/UMF) concept, the 3d ID was fielded with its MLRS equipment, completing all divisional fieldings of the system to Europe. 4 April 85 The first fielding of a continental United States (CONUS) battery under the TP/UMF concept was completed when C Battery of the 1st Battalion, 27th Field Artillery (FA), stationed at Fort Carson, Colorado, with the 4th ID (Mechanized), formally accepted its MLRS equipment. 31 May 85 A letter contract was definitized with LTV Aerospace and Defense (LTVAD) Company for integration of the TGW into the basic MLRS. This was a parallel effort to the TGW development contract awarded on 29 November 84, and included the basic work for a component demonstration substage (CDS). 19 June 85 Deployment to the Headquarters, Headquarters and Service (HHS) and A Batteries, 4th Battalion, 27th FA, located at Wertheim, Germany, with the VII Corps was accomplished. This marked the first total package fielding in a pure MLRS battalion (three batteries, each with nine launchers) in Europe. 7 January 86 Fielding of C Battery, 4/27th FA Battalion of VII Corps, marked the completion of the first pure MLRS battalion to be fielded in the U.S. Army, Europe (USAREUR). May 86 The European Executive Agency awarded the MLRS European production contract to the European Production Group, Munich, Germany. December 86 A letter contract was awarded to LTVAD to provide initial support for the integration of the Sense and Destroy Armor (SADARM) submunitions into the MLRS. The MLRS SADARM was a derivative of the existing MLRS rocket. It was envisioned that the descending submunition, using a dual-mode millimeter wave (MMW) and infrared (IR) sensor, would search for a target and after detecting it, fire an explosively formed penetrator to impact the target from the top. October 87 The United States and the Ministry of National Defense of the Republic of Turkey signed an MOU authorizing Turkey to co-produce selected MLRS major items. December 87 Fielding of an MLRS battalion to positioning of materiel configured to unit sets (POMCUS) stockages began with the deployment of Headquarters, Headquarters and Service Battery, A Battery, and B Battery, 16th Combat Equipment Company. July 88 A unit of the Oklahoma National Guard became the first National Guard unit to receive the MLRS system. September 88 LTVAD awarded a full-scale development (FSD) cost-plus-incentive-fee contract for the BCW program. 30 September 88 LTVAD received a cost-plus-incentive-fee FSD contract for the SADARM program. November 88 The European Production Qualification Test (EPQT) began at WSMR. FY 89 The development effort in support of the German AT2 warhead program was completed during the second quarter. FY 89 Transition of management responsibility for the BCW program to the PM for Binary Munitions was completed by the beginning of this year. March 89 The MLRS TGW program completed CDS. June 89 The last basic MLRS launcher was accepted. July 89 The European Production Qualification Test (EPQT) was successfully completed. 27 July 89 Delivery of "Deep Attack" M270 launchers began with a roll-out ceremony at the LTV Production Facility in Camden. The "Deep Attack" launchers were capable of firing Army TACMS missiles. 30 July 89 The TGW program entered the Revised System Demonstration Substage (SDS) with the award of the SDS contract. August 89 The European Fly-to-Buy (EFTB) program began at WSMR. 31 October 89 As part of the evaluation of the metal blast panel configuration for the front of the MLRS launcher, 60 MLRS practice rockets were successfully flight tested in consecutive 12-round ripples as quickly as could be executed. The metal blast panel was designed to protect the exposed areas of the M270 launcher from the extremely high velocity gases resulting from rocket motor operation. The new panels would replace the existing neoprene ablative panels that only provided protection from burn- through during firing for 108 rounds. While acceptable in peacetime, this limitation imposed severe restraints in battle. The design goal of providing protection for up to 540 rockets was exceeded during WSMR testing, where 700 rounds were fired with no panel degradation. This effort was later accelerated as part of the MLRS Project Office's support for Operation Desert Shield/Storm (ODS). FY 90 Total Package Fielding (TPF) of the first "Deep Attack" M270 launchers was completed for Batteries A and B, 2d Battalion, 32d FA, V Corps, USAREUR, as well as for Battery C, 3d Battalion, 9th Artillery, Fort Sill, Oklahoma. February 91 The 500th MLRS production launcher rolled out. February 91 The MLRS BCW program was cancelled. February 91 Because of a warhead failure during flight, the MLRS SADARM warhead structure was redesigned to include a different type of aluminum and a new method of assembly. 13 February 91 Alpha Battery, 21st FA launched the first MLRS munitions to be fired in combat. The system performed extremely well during ODS. MLRS units from other coalition members were also involved in Desert Storm and proved the value of the successful operation of the multinational system. November 91 Planning began on development of an ER-MLRS as a successor to the Basic M26 rocket then in production. The improved rocket would provide the potential to engage additional threat systems, improve accuracy, create a safer environment for friendly forces, and provide a low cost delivery vehicle for future smart munitions at extended ranges. 8 - 18 December 91 The Independent Software Integration Test (ISIT), a complex, contractor operated system level test, was successfully completed at Fort Sill. The test was conducted using the European Heavy Army Scenario and performed with tactical equipment. A major FDDM milestone, the ISIT demonstrated the FDDM's command, control, and communication capability from the Corps Fire Support Element to the MLRS launcher. This test was the pivotal event that proved the FDDM system hardware and software architecture met system design criteria and operated very effectively during an intense combat scenario. February 92 The European Production Line was successfully certified as an MLRS qualified second source. 28 February 92 Loral Vought Systems (LVS) received an Engineering and Manufacturing Develop-ment (EMD) contract for development of an Improved Fire Control System (IFCS). This award was the culmination of the FCS study chartered to determine how to mitigate MLRS electronics obsolescence while reducing long-term Operation and Support (O&S) costs as well as accommodating the future needs of M270 MFOM members. May 92 The United States formally notified France, Germany, and the United Kingdom that it would not be a full participant in FSD of the MLRS TGW. August 92 The MLRS Fire Direction Data Manager (FDDM)/Warrior demonstrated the potential of an Intelligence/Fire Support (INTEL/FS) battlefield functional area connection to support MFOM in a near realtime sensor-to-shooter scenario. The goals of the FDDM/ Warrior were to provide an automatic link between the Technical Collection and Analysis Elements (TCAE) and Fire Support Element (FSE) using available, state-of-the-art tactical systems which were ready to field as well as to enhance and expedite future interfaces already in concept and planning. 27 July 93 Full-scale production of the MLRS basic rocket ended. Minimum production of tactical warheads continued in order to maintain a warm production line. August 93 The MICOM Materiel Release Review Board (MRRB) approved the FDDM for fielding. September 93 AMC Headquarters approved the release of the FDDM. 27 September 93 The ceremony to hand off the first tactical FDDM to the 75th FA Brigade took place. 23 December 93 As a result of ODS reviews, the ER-MLRS program was established and an Engineering and Manufacturing Development (EMD) contract was signed with on this date with LVS. FY 94 The remaining tactical fleet of Basic MLRS was converted to Improved MLRS in the first and second quarters. FY 94 The TGW program was terminated at the conclusion of the Revised SDS. Only the French government continued development of the submunition, after the other three nations cooperating in the program chose not to continue the codevelopment effort. FY 94 The MLRS SADARM Program was terminated because of underfunding. June 94 The European Production Line completed delivery of the last European launcher. October 94 The German government conducted the first MLRS AT2 firing with live mines at WSMR. FY 95 The Modified (MOD) Dual Purpose Improved Conventional Munitions (DPICM) Advanced Concept Technical Demonstration (ACTD) was initiated after the U.S. Army identified a need to delay and disrupt multiple rocket launcher movement. A variant of the XM85 Self Destruct grenade carried by the ER-MLRS rocket, the MOD DPICM had its firing pin removed to keep the grenade from exploding on contact. The MOD DPICM incorporated a modified integrated chip providing a longer random delay in self destruct and an anti-disturbance sensor to prevent tampering or neutralization. A two-phase test program was developed. FY 95 All scheduled FDDM fieldings were completed. All DA approved units were fully equipped and trained. 18 August 95 The contract for development of the Improved Launcher Mechanical System (ILMS) was awarded. This modification of the MLRS M270 launcher would allow faster engagement of highly mobile, short dwell time targets. November 95 The last European FTB was concluded. FY 96 The Bat-On-A-Rocket (BOAR) Demonstration Program was designed to show that the Army TACMS/Brilliant Antitank (BAT) submunition could be successfully integrated into an MLRS rocket. Managed by the Research, Development, and Engineering Center (RDEC), the program concluded with the successful dispense of a BAT submunition simulant. May 96 Approval was given for the ER-MLRS program to enter Low Rate Initial Production (LRIP). July 96 A contract for the initial quantity of ER-MLRS rockets was awarded. February 96 LVS received an ACTD letter contract for developing and manufacturing four prototypes for the MLRS High Mobility Artillery Rocket System (HIMARS). The HIMARS mission was to provide a C-130 transportable MLRS. |

MLRS Photos

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|