Basing Information

All AJAX and HERCULES sites recently surveyed from To Defend and Deter: The Legacy of the United States Cold War Missile Program by John C. Lonnquest and David F. Winkler

Options

1. Part 1, Alaska to Michigan - 1.5MBs (pdf)

2. Part 2, Minnesota to Wisconsin - 1.4MBs (pdf)

3. Summary - 68kb (pdf)

View more NIKE-AJAX photos

Summary

In 1954, the U.S. Army deployed the world's first operational, guided, surface-to-air missile system. This system, the Nike Ajax, was conceived near the end of World War II and developed during the early years of the Cold War. With an increasing perception of a direct Soviet bomber threat to the American mainland, the Army rushed Nike Ajax into production and deployed the missile system around key urban, military, and industrial locations.

The Nike Ajax contractor, Western Electric's Bell Telephone Laboratories, teamed with numerous subcontractors to produce 350 missile batteries for domestic and overseas deployment. The primary subcontractor, Douglas Aircraft, built 13,714 missiles at its Santa Monica plant and at the Army Ordnance Missile Plant located at Charlotte, North Carolina.

By 1958, the Army deployed nearly 200 Nike Ajax batteries around the nation's cities and vital military installations. Soon thereafter, the Army began gradually deactivating the Nike Ajax batteries and replacing them with the longer-range nuclear-capable Nike Hercules. The Army Air Defense Command (ARADCOM) deactivated the last Nike Ajax batteries guarding the Norfolk, Virginia, area in late 1963.

Technical Specifications

Length: 21 feet (34 feet 10 inches with booster)

Diameter: 12 inches

Wingspan: 4 feet, 6 inches

Weight: 1,000 pounds (over 2,455 pounds with booster)

Missile fuel/oxidizer: M3, a combination of JP4 jet fuel and starter fluid consisting initially of aniline/furfuryl alcohol, later dimethyl-hydrazine, and finally, red fuming nitric acid (IRFNA)

Booster fuel: Solid propellant

Range: 25 to 30 miles

Speed: Mach 2.3 (1,679 mph)

Altitude: Up to 70,000 feet

Guidance: Command by electronic computer and radar

Warhead: Three high-explosive fragmentation warheads mounted in the nose, center, and aft sections

Contractors

Airframe: Douglas Aircraft Company Santa Monica, California

Propulsion: Booster: Hercules Powder Company Radford Arsenal, Virginia

Sustainer: Bell Aircraft Company Buffalo, Nexv York

Guidance: Western Electric Company New York, New York

System Operation

The Nike Ajax command guidance system received guidance information from a computer on the ground. Designed to engage faster and higher-flying aircraft beyond the range of conventional antiaircraft artillery, the Nike system depended on technological advances in radar and computers made during and after World War II.

A series of events preceded any missile launch. First, an Air Defense Command Post sent warning to the battery of an imminent attack. Sirens would send personnel scurrying to their assigned battle stations. At the launching area, personnel conducted last minute pre-firing checks and positioned the missiles on the launchers.

As personnel readied the missiles, the incoming aircraft was picked up on a long-range acquisition radar. For the Nike Ajax system, this radar was known as LOPAR for "Low-Power Acquisition Radar." The LOPAR search radar antenna rotated constantly at a predetermined speed. When targets appeared on the scope, the battery commander used "electronic interrogation" to determine if the target was friend or foe.

Once the LOPAR operator designated a target as hostile, this information was transferred to a target-tracking radar (TTR). The TTR determined the target's azimuth, elevation, and range, and then automatically provided that information to a computer for use in guiding the Nike Ajax missile. Once energized, the guidance computer received a running account of the target's changing position.

Adjacent to the TTR, the missile-tracking radar (MTR) locked onto the missile selected to perform the intercept. When the hostile aircraft came within the battery's range, the battery commander launched the missile. After producing 59,000 pounds of thrust within 3 seconds to push the missile off the launch rail, the missile booster dropped away. Having ignited, the missile accelerated through the sound barrier. Once the missile was in the air, the MTR received continuous data on the missile's flight. In turn, by receiving updates from the TTR, the computer generated course correction information that was transmitted to guide the missile toward the target. At the predicted intercept point, the computer transmitted a burst signal that detonated the three high-explosive warheads.

One of the major flaws of the Ajax guidance system was that it could engage only one target at a time. Also, when the system first deployed, there was no provision for coordinating fire between multiple batteries. Thus, several different batteries could engage the same target and allow other targets to pass through. To alleviate this problem, ARADCOM established command centers where incoming targets were manually plotted and engagement orders were passed to the batteries. However, the inadequacies of this voice command and control system became immediately apparent during defense exercises, which sent the Army scrambling for a new solution.

Introduced in the late 1950s, the Interim Battery Data Link (IBDL) provided a "real-time" target data link between the batteries so that battery commanders could readily see what targets other batteries were actively engaging.

While IBDL was being deployed, the Army tested a successor system called "Missile Master" at Fort Meade, Maryland. After this system was proven within the Baltimore-Washington Defense Area, other major defense areas began receiving the Missile Master (AN/FSG-l) systems. Missile Master was the first truly integrating command and control system featuring automatic data communications, processing, and display equipment. By eliminating voice communications, this Martin-built system allowed an area commander to use all his batteries to engage up to 24 different targets.

Smaller defense areas with fewer batteries received another command and control system called the Battery Integration and Radar Display Equipment "BIRDIE" (AN/GSG-5).

Developmental History

In 1944, German advances in rocketry and jet aircraft, as well as the ability of bombers to fly at higher altitudes, brought to Army planners a somber realization that traditional antiaircraft artillery weaponry soon faced obsolescence. As a result of internal studies verifying the need for a "major caliber anti-aircraft rocket torpedo," the Army Chief of Ordnance issued a contract in February 1945 for Western Electric and Bell Telephone Laboratories (BTL) to determine the feasibility of such a weapon system. Army Ordnance based its selection of Western Electric/BTL on the team's experience in developing and producing gun directors and tracking radars.

Reporting back in mid-1945 that such an antiaircraft missile system was indeed feasible, Western Electric/BTL presented the parameters of a proposed system that came remarkably close to the system actually fielded 8 years later. The Army selected Western Electric as the prime contractor to develop the missile system. BTL maintained control of computer and radar development and worked with the Ballistics Research Laboratory at Aberdeen Proving Ground, Maryland, in determining the optimum shape of the warhead. Picatinny Arsenal, New Jersey, received responsibility for developing the High-Explosive (HE) fragmentation device that would be placed in the warhead, while Frankford Arsenal, Pennsylvania, created the fusing device.

The Douglas Aircraft Company became a major subcontractor, responsible for aerodynamic studies on the interceptor missile. Aerojet Engineering supplied both the liquid-fueled sustainer engine and the solid-fueled booster rockets. The initial design called for eight booster rockets to be wrapped around the tail of the missile. The development schedule projected a weapon system ready for production in 1949. This schedule was not met.

The first static firing of a Nike missile occurred at White Sands Proving Ground, New Mexico, on September 17, 1946. The missile was returned to Douglas's Santa Monica plant for evaluation. A week after the first static test, the first actual launch of a missile occurred at White Sands. Several other "uncontrolled flight" launchings occurred that fall, with one missile reaching an altitude of 140,000 feet. Instead of warheads, these missiles carried onboard cameras to record instrument readings throughout the flight.

Launches at White Sands continued in 1947. Meanwhile, tracking experiments proceeded at Whippany, New Jersey, using an experimental monopulse radar.

By 1948 the missile project had fallen behind schedule. Problems with the reliability of the cluster booster configuration forced designers to adapt an Allegheny Ballistics Laboratory booster that had been developed for the Navy's antiaircraft missile program. With this single solid-fuel booster, the missile took on an elongated appearance as the missile now sat piggy-back on top of the booster. Launchings at White Sands now tested for roll stabilization and steering controls. Problems were resolved only after tedious study of telemetry records.

Technical advances continued at both White Sands and BTL. These advances sufficiently impressed the DoD Director of Guided Missiles, K.T. Keller, in October 1950 to recommend acceleration of the program. Despite the fact that system testing was still ongoing, the Army let a contract in January 1951 for Western Electric, BTL, and Douglas Aircraft to produce 1,000 Nike Ajax missiles (or the Nike I as it was then called) and 60 sets of ground equipment.

The Army's faith was justified when on November 27, 1951, a Nike successfully engaged a QB-17 drone over the skies of New Mexico. During the following April additional tests with live warheads further impressed VIPs visiting at White Sands. By July 1952, the first production-line Nike was launched. Testing continued to evaluate the missile and improve the reliability of the production models. By the following summer, the contractors were ready to turn over a complete missile battery to the Army Anti-Aircraft Command (ARAACOM). Soon soldiers were training to operate and maintain the system.

Over the next few years, hundreds of Nike Ajax missiles streaked across the southern New Mexico sky as battery crews, called "packages," trained at nearby Fort Bliss. Texas, before deploying. Later, most of these men returned to Fort Bliss to fire additional missiles during Annual Service Practices (ASPs). Beginning in 1957, many of the men who underwent initial training were National Guardsmen.

Basing Strategy

The Nike Ajax system was designed to supplement and then replace gun batteries deployed around the nation's major urban areas and vital military installations. ARAACOM's original basing strategy projected a central missile assembly point from which missiles would be taken out to prepared above-ground launch racks ringing the defended area. However, ARAACOM discarded this semimobile concept because the system needed to be ready for instantaneous action to fend off a "surprise attack." Instead, a fixed-site scheme was devised.

Due to geographical factors, the placement of Nike Ajax batteries differed at each location. In Chicago, for example, the broad expanse of Lake Michigan forced ARAACOM to erect batteries along the lakefront near the heart of the city. In planning Chicago and other area defenses, ARAACOM planners carefully examined all possible enemy aircraft approaches to ensure no gaps were left open. Initially, the planners chose fixed sites well away from the defended area and the Corps of Engineers Real Estate Offices began seeking tracts of land in rural areas. However, in late 1952, the planners determined that close-in perimeter sites would provide enhanced firepower Staggering sites between outskirt and close-in locations gave defenders a greater defense-in-depth capability. The Corps of Engineers Real Estate Offices recognized that projected acreage requirements of 119 acres per site would not be feasible in some of the urban areas selected for missile deployment. To solve this problem, design architect Leon Chatelain, Jr., devised an underground magazine configuration that cut the land requirement down to 40 acres.

The Army constructed a prototype magazine at White Sands in June 1953 and fired missiles from the magazine elevator platform to demonstrate the design's practicality With the design proven, Chatelain, along with the architectural firm of Spector and Montgomery, began preparing drawings for nationwide distribution. On October 28, 1953, ARAACOM directed that the underground magazine design would be used in most cases.

To minimize land acquisition costs, public lands were to be used whenever possible, even at the cost of tactical considerations. Often the only public lands available were parklands. Occasionally the Army had to confront local citizens who opposed the use of parkland and were concerned with public safety. Most of the time, the Army had no choice but to acquire private property. Some private landowners, not understanding the very restrictive requirements for a Nike installation, assumed Army land demands were made either arbitrarily or capriciously. Occasionally local opposition succeeded in getting the Army to move a planned site to a new location.

Once the land was acquired, local Corps of Engineer Districts contracted with private construction firms to execute the Chatelain plans.

Nike Ajax Deployment

The first Nike Ajax unit deployed to an above-ground site at Fort Meade, Maryland, in March 1954. Over the next 4 years, nearly 200 batteries were constructed around the majority of America's major northern tier and coastal cities. In June 1958, a process of conversion to the longer range Nike Hercules missile began. Subsequently, the Nike Ajax batteries were either modified to accept the new missile or deactivated. In November 1963, Site N-63 guarding Norfolk, Virginia, was the last Nike Ajax battery to be deactivated. However, the Nike Ajax missile continued service overseas with the U.S. Army and with the military forces of America's allies for many more years.

Site Configuration

Each Nike missile battery was divided into three principle areas: the administrative area, integrated fire control area (IFC), and the launch area. The administrative area was usually collocated within the IFC or launch areas. The IFC and launch areas were separated by at least 1,000 yards, often over a mile, but were within visual sight of each other

The administrative area included barracks, a mess hall, and a recreation/administration supply building. These buildings were typically one-story cinder block structures with flat roofs. The area also contained a large motor maintenance building with wash and grease racks and a fuel tank with a gasoline pump.

The IEC hosted the three acquisition and tracking radars as well as the battery control trailer, radar control trailer, maintenance and spares trailer, power plant, and electric cabling system.

The battery control trailer contained the missile guidance computer, the acquisition radar scope and controls, and the telephone switchboard. From here the battery commander identified targets and directed missile launches. The radar control trailer held controls and electronic equipment for the TTR and MTR. The maintenance and spares trailer contained test equipment and spare parts. Three 400-cycle diesel-driven generators were installed to provide electrical power to this area. The electric cabling system transmitted data within the control area and to the launch area. A collimation test mast was placed at each battery control area to provide a common reference point for adjusting the radars.

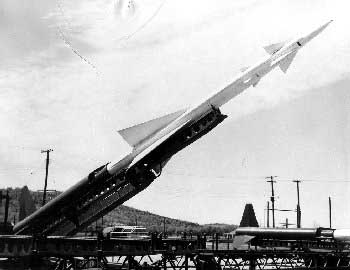

The first Nike sites featured above-ground launchers. This quickly changed as land restrictions forced the Army to construct space-saving underground magazines. Capable of hosting 12 Nike Ajax missiles, each magazine had an elevator that lifted the missile to the surface in a horizontal position. Once above ground, the missile could be pushed manually along a railing to a launcher placed parallel to the elevator. Typically four launchers sat atop the magazine.

Near the launchers, a trailer housed the launch control officer and the controls he operated to launch missiles. In addition to the launch control trailer, the launch area contained a generator building with three diesel generators, frequency converters, and missile assembly and maintenance structures.

*From To Defend and Deter: The Legacy of the United States Cold War Missile Program, John C. Lonnquest and David F. Winkler, USACERL Special Report 97/01, November 1996. Cleared for unlimited public release by the U.S. Army Construction Engineering Research Laboratories, Champaign, IL. Printed by the Defense Publishing Service, Rock Island, IL.

** SAM-A-7 was the designation before 1962; MIM-3, 3A were the designations used after 1962.

NIKE AJAX Photos

|

|

|

|

|

|

|

|

|